Manufacturing Process of Steel Forging Parts

Steel Open-die Forging

Steel open-die forging is to deform the steel after heating it through the direct action of a forging hammer or press, gradually forming it into the desired shape and size.

· High flexibility, no mold required, and can process steel forgings of various shapes

· Can manufacture large, high-strength steel forgings

· Low manufacturing cost, suitable for single-piece and small-batch production.

Steel Closed Die Forging

Steel closed die forging is to heat the metal material to a certain temperature and then forge it through a special closed die. It can produce steel forgings with high precision, excellent mechanical properties and good surface quality.

· Suitable for mass production

· High dimensional accuracy of steel forgings

· Excellent mechanical properties of steel forgings

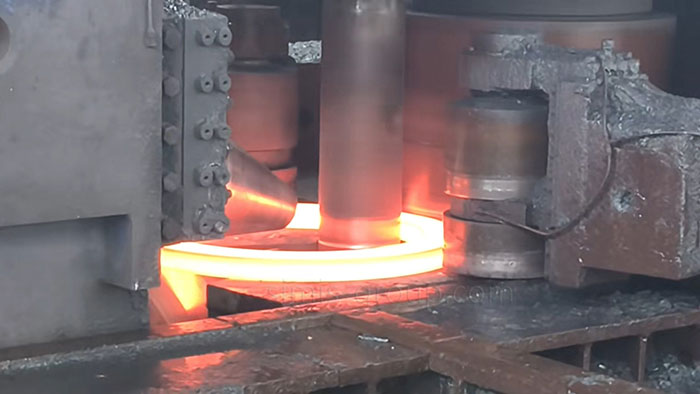

Steel Ring Forging

Steel ring forging is specially used to produce ring parts. After heating the steel blank, it is placed in a mold or forging equipment, and pressure is applied to force the metal to flow into the mold cavity to form a steel ring forging.

· Used to make parts with complex shapes

· Suitable for medium and large-scale production

· Forgings have high strength and toughness

Steel Cold Forging

Steel cold forging is the process of plastically deforming a steel blank by applying pressure at room temperature without heating, thereby achieving high precision and improved mechanical properties.

· Tight tolerances and good surface finish

· Increased strength and hardness of the steel, improving durability

· Reduced material waste and the need for secondary processing

· Steel forgings have higher strength and toughness

Heat Treatment

Heat treatment is to change the internal structure and properties of steel materials by heating, heat preservation and cooling, improve the mechanical properties of steel, extend service life and optimize processing performance.

· Improve the hardness and strength of steel materials

· Improve the toughness of steel materials

· Improve wear resistance and corrosion resistance

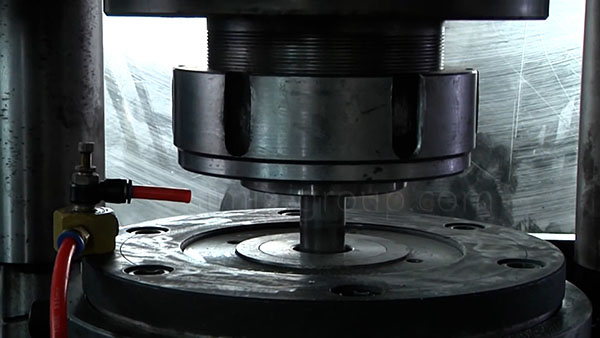

Machining

Machining is a post-processing process for steel forings, which improves the accuracy, surface quality and functionality of forgings through fine processing.

· Optimize appearance quality

· Improve part structure and function

· Process thin walls and complex shapes

Different Materials of Steel Forgings

1. Carbon steel

Forging carbon steel involves heating it to a ductile state and then applying pressure using a hammer, press, or other forging equipment to form it. The forging process significantly refines the grain structure, eliminates internal defects, and improves mechanical properties, making it suitable for critical components requiring high reliability and strength.

· Superior Mechanical Properties: Forging refines the grain structure and improves density, resulting in higher tensile strength, better fatigue resistance, and improved impact toughness compared to cast or machined carbon steel components.

· Excellent Structural Integrity: The forging process eliminates porosity, shrinkage cavities, and other internal defects common in castings, ensuring higher reliability and safety factor.

· Continuous Grain Flow: The grain structure follows the contour of the part shape, providing optimal strength distribution and enhanced resistance to fatigue failure and impact loading.

· Cost-Effectiveness for High-Volume Production: For complex shapes in large quantities, forging can be more economical than machining from solid stock while providing better mechanical properties.

· Good Machinability: Forged carbon steel maintains good machinability in normalized or annealed condition, allowing for precision finishing operations.

Forged Carbon Steel Components by Simis Steel Forging Factory:

Automotive crankshafts and connecting rods; gears and transmission shafts; hand tools (wrenches, pliers, hammers); construction machinery components; railway axles and wheels; industrial equipment shafts and couplings.

Forged Carbon Steel Categories used by Simis Steel Forging Factory:

· Low Carbon Steel Forgings (Carbon content ≤ 0.25%)

Common Applications: General structural components, automotive body parts, construction hardware, and case-hardened components.

Common Grades: SAE 1008, 1010, 1015; ASTM A668 Class A

· Medium Carbon Steel Forgings (Carbon content 0.25% - 0.60%)

Common Applications: Automotive crankshafts, connecting rods, gears, axles, and high-strength structural components.

Common Grades: SAE 1045, 1050; ASTM A668 Class D (C45)

· High Carbon Steel Forgings (Carbon content ≥ 0.60%)

Common Applications: Cutting tools, springs, high-strength wire, wear-resistant components, and railway wheels.

Common Grades: SAE 1060, 1070, 1080; ASTM A668 Class G

· Free-Cutting Carbon Steel Forgings

Common Applications: High-volume production parts requiring extensive machining, such as fasteners, fittings, and automotive components.

Common Grades: SAE 1117, 1144; ASTM A668 Class C

2. Stainless steel

Forged stainless steel is produced by heating and compressing a stainless steel billet. Forging refines the stainless steel's grain structure and improves its overall performance. Compared to casting or machining, forging significantly enhances mechanical properties, corrosion resistance, and structural reliability, making it particularly suitable for manufacturing critical components in corrosive, high-temperature, and high-pressure environments.

· Enhanced Mechanical Properties: Forging refines the grain structure, resulting in higher tensile strength, improved fatigue resistance, and better impact toughness compared to cast or machined stainless steel components.

· Superior Corrosion Resistance: The forging process eliminates surface defects and internal porosity, enhancing the material's resistance to corrosive environments.

· Excellent Structural Integrity: Forging eliminates internal defects such as shrinkage cavities and porosity, ensuring higher reliability and longer service life.

· Good High-Temperature Performance: Maintains strength and oxidation resistance at elevated temperatures, suitable for high-temperature applications.

· Excellent Surface Quality: Forged surfaces have better finish and integrity, reducing the need for extensive machining and surface treatment.

Forged Stainless Steel Components by Simis Steel Forging Factory:

Valves and pump components for chemical processing; marine hardware and propeller shafts; aerospace engine components; medical implants and surgical instruments; food processing equipment.

Forged Stainless Steel Categories used by Simis Steel Forging Factory:

· Austenitic Stainless Steel Forgings

Common Applications: Chemical processing equipment, food handling machinery, medical devices, and architectural components.

Common Grades: ASTM A182 F304 (18Cr-8Ni), F316 (18Cr-10Ni-2Mo), F321 (18Cr-10Ni-Ti)

· Martensitic Stainless Steel Forgings

Common Applications: Surgical instruments, pump shafts, valve parts, and mechanical components requiring high strength.

Common Grades: ASTM A182 F410 (13Cr), F420 (13Cr-0.3C), F440C (18Cr-1C-1Mo)

· Duplex Stainless Steel Forgings

Common Applications: Offshore oil and gas equipment, chemical processing vessels, desalination plants, and high-strength structural components.

Common Grades: ASTM A182 F51 (22Cr-5Ni-3Mo-N), F53 (25Cr-7Ni-4Mo-N), F55 (25Cr-7Ni-4Mo-Cu-W-N)

3. Alloy steel

Forged alloy steel significantly improves the strength, toughness and hardenability of alloy steel, making it particularly suitable for critical components under high stress, high wear and harsh service conditions.

· Enhanced Mechanical Properties: Forging refines the grain structure and eliminates defects, resulting in superior tensile strength, improved fatigue resistance, and exceptional impact toughness.

· Excellent Hardenability: Alloying elements (Cr, Ni, Mo, V) enable deeper and more uniform hardening during heat treatment, allowing production of large, high-strength components.

· Improved Wear Resistance: The combination of alloying elements and forging process provides excellent resistance to abrasion and surface degradation.

· Good High-Temperature Performance: Maintains strength and creep resistance at elevated temperatures, suitable for high-temperature applications.

· Superior Fatigue Strength: The continuous grain flow pattern provides excellent resistance to cyclic loading and extends service life.

Forged Alloy Steel Components by Simis Steel Forging Factory:

Gears and transmission shafts; crankshafts and connecting rods; high-pressure valve bodies; turbine blades and disks; mining equipment components; aerospace structural parts; heavy machinery components.

Forged Alloy Steel Categories used by Simis Steel Forging Factory:

· Chromium-Molybdenum (Cr-Mo) Alloy Steel Forgings

Common Applications: Pressure vessels, piping systems, turbine components, and high-strength structural parts.

Common Grades: ASTM A182 F11 (1.25Cr-0.5Mo), F22 (2.25Cr-1Mo); SAE 4130, 4140

· Nickel-Chromium-Molybdenum (Ni-Cr-Mo) Alloy Steel Forgings

Common Applications: Aircraft landing gear, high-strength bolts, crankshafts, and critical automotive components.

Common Grades: SAE 4340, 4340H; ASTM A182 F4340; EN 1.6582 (34CrNiMo6)

· Chromium-Vanadium (Cr-V) Alloy Steel Forgings

Common Applications: Hand tools, springs, high-strength fasteners, and wear-resistant components.

Common Grades: SAE 6150 (1Cr-0.2V); EN 1.8159 (50CrV4)

· Boron-Alloyed Steel Forgings

Common Applications: High-strength fasteners, automotive components, and general engineering parts requiring good hardenability.

Common Grades: SAE 15B21, 15B30, 15B35

4. Special purpose forged steel

Forged specialty steels can enhance specific properties such as wear resistance, corrosion resistance or special physical properties, making these special steel materials ideal for extreme service conditions and special applications.

· Exceptional Specialized Properties: Forging optimizes the unique characteristics of these steels, including extreme hardness, special corrosion resistance, or specific physical properties.

· Superior Structural Integrity: The forging process eliminates internal defects and creates a dense, homogeneous structure, ensuring reliability in critical applications.

· Excellent Performance Stability: Maintains consistent performance under extreme conditions including high temperature, high pressure, and corrosive environments.

· Good Processability: Despite their specialized properties, these steels can be forged into complex shapes while maintaining their characteristic performance.

· Long Service Life: The combination of forged density and specialized properties ensures extended service life in demanding applications.

Forged Special Purpose Steel Components by Simis Steel Forging Factory:

Extreme wear-resistant mining equipment; corrosion-resistant chemical processing components; high-temperature power generation parts; special electrical and magnetic components.

Forged Special Purpose Steel Categories used by Simis Steel Forging Factory:

· Corrosion-Resistant Special Steel Forgings

Common Applications: Chemical processing equipment, marine engineering components, pollution control equipment.

Common Grades: ASTM A182 F44 (UNS S31254), F55 (UNS S32760), F61 (UNS N06625)

· Heat-Resistant Steel Forgings

Common Applications: Gas turbine blades and disks, steam turbine rotors, engine exhaust valves, industrial furnace components, petrochemical cracking tubes.

Common Grades: ASTM A182 F11 (1.25Cr-0.5Mo), F22 (2.25Cr-1Mo), F91 (9Cr-1Mo-V); SAE 3140 (40CrNiMoA)

· Wear-Resistant Steel Forgings

Common Applications: Mining equipment (crusher jaws, hammer heads), cement mixer liners, railroad frogs and crossings, agricultural machinery parts, excavator teeth.

Common Grades: ASTM A532 Class II Type D, AR400/AR500, SAE 4340

· Electrical and Magnetic Steel Forgings

Common Applications: Generator rotor forgings, transformer cores, electrical machinery components.

Common Grades: ASTM A848 Grade 1 (Low Carbon Magnetic), A867 Grade 1 (Silicon Electrical Steel)

1. Carbon steel

Forging carbon steel involves heating it to a ductile state and then applying pressure using a hammer, press, or other forging equipment to form it. The forging process significantly refines the grain structure, eliminates internal defects, and improves mechanical properties, making it suitable for critical components requiring high reliability and strength.

· Superior Mechanical Properties: Forging refines the grain structure and improves density, resulting in higher tensile strength, better fatigue resistance, and improved impact toughness compared to cast or machined carbon steel components.

· Excellent Structural Integrity: The forging process eliminates porosity, shrinkage cavities, and other internal defects common in castings, ensuring higher reliability and safety factor.

· Continuous Grain Flow: The grain structure follows the contour of the part shape, providing optimal strength distribution and enhanced resistance to fatigue failure and impact loading.

· Cost-Effectiveness for High-Volume Production: For complex shapes in large quantities, forging can be more economical than machining from solid stock while providing better mechanical properties.

· Good Machinability: Forged carbon steel maintains good machinability in normalized or annealed condition, allowing for precision finishing operations.

Forged Carbon Steel Components by Simis Steel Forging Factory:

Automotive crankshafts and connecting rods; gears and transmission shafts; hand tools (wrenches, pliers, hammers); construction machinery components; railway axles and wheels; industrial equipment shafts and couplings.

Forged Carbon Steel Categories used by Simis Steel Forging Factory:

· Low Carbon Steel Forgings (Carbon content ≤ 0.25%)

Common Applications: General structural components, automotive body parts, construction hardware, and case-hardened components.

Common Grades: SAE 1008, 1010, 1015; ASTM A668 Class A

· Medium Carbon Steel Forgings (Carbon content 0.25% - 0.60%)

Common Applications: Automotive crankshafts, connecting rods, gears, axles, and high-strength structural components.

Common Grades: SAE 1045, 1050; ASTM A668 Class D (C45)

· High Carbon Steel Forgings (Carbon content ≥ 0.60%)

Common Applications: Cutting tools, springs, high-strength wire, wear-resistant components, and railway wheels.

Common Grades: SAE 1060, 1070, 1080; ASTM A668 Class G

· Free-Cutting Carbon Steel Forgings

Common Applications: High-volume production parts requiring extensive machining, such as fasteners, fittings, and automotive components.

Common Grades: SAE 1117, 1144; ASTM A668 Class C

2. Stainless steel

Forged stainless steel is produced by heating and compressing a stainless steel billet. Forging refines the stainless steel's grain structure and improves its overall performance. Compared to casting or machining, forging significantly enhances mechanical properties, corrosion resistance, and structural reliability, making it particularly suitable for manufacturing critical components in corrosive, high-temperature, and high-pressure environments.

· Enhanced Mechanical Properties: Forging refines the grain structure, resulting in higher tensile strength, improved fatigue resistance, and better impact toughness compared to cast or machined stainless steel components.

· Superior Corrosion Resistance: The forging process eliminates surface defects and internal porosity, enhancing the material's resistance to corrosive environments.

· Excellent Structural Integrity: Forging eliminates internal defects such as shrinkage cavities and porosity, ensuring higher reliability and longer service life.

· Good High-Temperature Performance: Maintains strength and oxidation resistance at elevated temperatures, suitable for high-temperature applications.

· Excellent Surface Quality: Forged surfaces have better finish and integrity, reducing the need for extensive machining and surface treatment.

Forged Stainless Steel Components by Simis Steel Forging Factory:

Valves and pump components for chemical processing; marine hardware and propeller shafts; aerospace engine components; medical implants and surgical instruments; food processing equipment.

Forged Stainless Steel Categories used by Simis Steel Forging Factory:

· Austenitic Stainless Steel Forgings

Common Applications: Chemical processing equipment, food handling machinery, medical devices, and architectural components.

Common Grades: ASTM A182 F304 (18Cr-8Ni), F316 (18Cr-10Ni-2Mo), F321 (18Cr-10Ni-Ti)

· Martensitic Stainless Steel Forgings

Common Applications: Surgical instruments, pump shafts, valve parts, and mechanical components requiring high strength.

Common Grades: ASTM A182 F410 (13Cr), F420 (13Cr-0.3C), F440C (18Cr-1C-1Mo)

· Duplex Stainless Steel Forgings

Common Applications: Offshore oil and gas equipment, chemical processing vessels, desalination plants, and high-strength structural components.

Common Grades: ASTM A182 F51 (22Cr-5Ni-3Mo-N), F53 (25Cr-7Ni-4Mo-N), F55 (25Cr-7Ni-4Mo-Cu-W-N)

3. Alloy steel

Forged alloy steel significantly improves the strength, toughness and hardenability of alloy steel, making it particularly suitable for critical components under high stress, high wear and harsh service conditions.

· Enhanced Mechanical Properties: Forging refines the grain structure and eliminates defects, resulting in superior tensile strength, improved fatigue resistance, and exceptional impact toughness.

· Excellent Hardenability: Alloying elements (Cr, Ni, Mo, V) enable deeper and more uniform hardening during heat treatment, allowing production of large, high-strength components.

· Improved Wear Resistance: The combination of alloying elements and forging process provides excellent resistance to abrasion and surface degradation.

· Good High-Temperature Performance: Maintains strength and creep resistance at elevated temperatures, suitable for high-temperature applications.

· Superior Fatigue Strength: The continuous grain flow pattern provides excellent resistance to cyclic loading and extends service life.

Forged Alloy Steel Components by Simis Steel Forging Factory:

Gears and transmission shafts; crankshafts and connecting rods; high-pressure valve bodies; turbine blades and disks; mining equipment components; aerospace structural parts; heavy machinery components.

Forged Alloy Steel Categories used by Simis Steel Forging Factory:

· Chromium-Molybdenum (Cr-Mo) Alloy Steel Forgings

Common Applications: Pressure vessels, piping systems, turbine components, and high-strength structural parts.

Common Grades: ASTM A182 F11 (1.25Cr-0.5Mo), F22 (2.25Cr-1Mo); SAE 4130, 4140

· Nickel-Chromium-Molybdenum (Ni-Cr-Mo) Alloy Steel Forgings

Common Applications: Aircraft landing gear, high-strength bolts, crankshafts, and critical automotive components.

Common Grades: SAE 4340, 4340H; ASTM A182 F4340; EN 1.6582 (34CrNiMo6)

· Chromium-Vanadium (Cr-V) Alloy Steel Forgings

Common Applications: Hand tools, springs, high-strength fasteners, and wear-resistant components.

Common Grades: SAE 6150 (1Cr-0.2V); EN 1.8159 (50CrV4)

· Boron-Alloyed Steel Forgings

Common Applications: High-strength fasteners, automotive components, and general engineering parts requiring good hardenability.

Common Grades: SAE 15B21, 15B30, 15B35

4. Special purpose forged steel

Forged specialty steels can enhance specific properties such as wear resistance, corrosion resistance or special physical properties, making these special steel materials ideal for extreme service conditions and special applications.

· Exceptional Specialized Properties: Forging optimizes the unique characteristics of these steels, including extreme hardness, special corrosion resistance, or specific physical properties.

· Superior Structural Integrity: The forging process eliminates internal defects and creates a dense, homogeneous structure, ensuring reliability in critical applications.

· Excellent Performance Stability: Maintains consistent performance under extreme conditions including high temperature, high pressure, and corrosive environments.

· Good Processability: Despite their specialized properties, these steels can be forged into complex shapes while maintaining their characteristic performance.

· Long Service Life: The combination of forged density and specialized properties ensures extended service life in demanding applications.

Forged Special Purpose Steel Components by Simis Steel Forging Factory:

Extreme wear-resistant mining equipment; corrosion-resistant chemical processing components; high-temperature power generation parts; special electrical and magnetic components.

Forged Special Purpose Steel Categories used by Simis Steel Forging Factory:

· Corrosion-Resistant Special Steel Forgings

Common Applications: Chemical processing equipment, marine engineering components, pollution control equipment.

Common Grades: ASTM A182 F44 (UNS S31254), F55 (UNS S32760), F61 (UNS N06625)

· Heat-Resistant Steel Forgings

Common Applications: Gas turbine blades and disks, steam turbine rotors, engine exhaust valves, industrial furnace components, petrochemical cracking tubes.

Common Grades: ASTM A182 F11 (1.25Cr-0.5Mo), F22 (2.25Cr-1Mo), F91 (9Cr-1Mo-V); SAE 3140 (40CrNiMoA)

· Wear-Resistant Steel Forgings

Common Applications: Mining equipment (crusher jaws, hammer heads), cement mixer liners, railroad frogs and crossings, agricultural machinery parts, excavator teeth.

Common Grades: ASTM A532 Class II Type D, AR400/AR500, SAE 4340

· Electrical and Magnetic Steel Forgings

Common Applications: Generator rotor forgings, transformer cores, electrical machinery components.

Common Grades: ASTM A848 Grade 1 (Low Carbon Magnetic), A867 Grade 1 (Silicon Electrical Steel)

Application Of Steel Forgings

Custom Steel Forgings by Simis Forging Factory

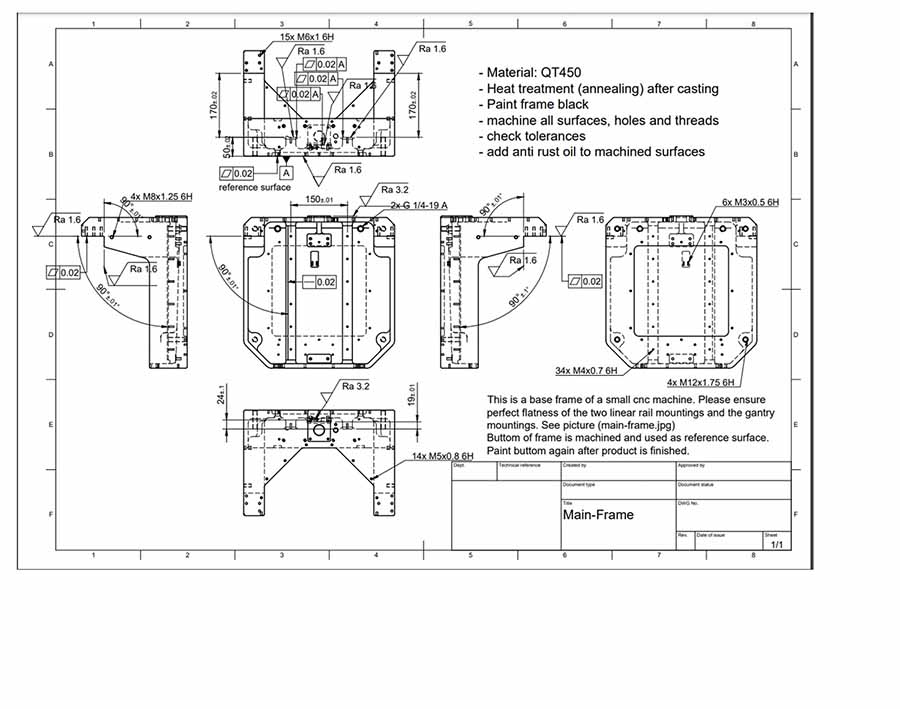

Steel Forging Company's Custom Steps

Confirm customization requirements

1. Provide detailed design documents or samples of parts

The Simis engineering team will analyze the 3D drawings (CAD models) and processing drawings of forgings provided by customers to ensure that they meet the manufacturing requirements.

Samples: If customers can provide samples, we can also forge and replicate them according to the samples.

2. Confirm the performance requirements of steel forgings

Clearly define the various performance requirements of forgings, such as strength, hardness, wear resistance, corrosion resistance, etc., and confirm the surface roughness, appearance quality, dimensional tolerance and accuracy requirements of forgings.

3. Confirm the forging material

Select the appropriate forging material according to the use environment, technical requirements or customer requirements of the parts. Simis will give reasonable suggestions based on the price, mechanical properties, wear resistance, corrosion resistance, etc. of the material.

4. Confirm the steel forging process

Determine the appropriate steel forging process based on the price, shape, size, accuracy, material, etc. of the parts.

5. Make samples

Forge the selected forging materials through the corresponding process to produce the first batch of samples.

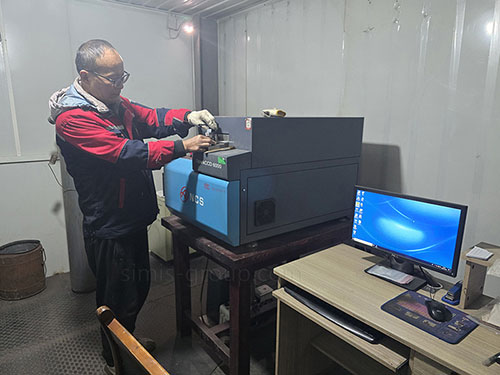

6. Comprehensive inspection of samples

The produced samples will be fully inspected to ensure that they meet the design standards and customer quality requirements.

Dimension and tolerance inspection, performance testing, chemical composition analysis, non-destructive testing and other test reports

Production and quality control

7. Mass production

After the sample is confirmed and approved by the customer, the mass production schedule is arranged according to the order requirements, and the production materials are prepared. The same forging equipment and process as the sample stage are used in the mass production process.

8. Mass production quality control

We implement strict quality control measures during the production process to ensure that the quality of each steel forgings in mass production meets customer requirements. During the production process, the size, appearance, physical properties, etc. of the steel forgings are regularly inspected to ensure the consistency of each batch of parts.

9. Post-production product quality inspection

Multiple inspections by multiple people: We will arrange different inspectors to conduct multiple random inspections on the final product, including dimensional accuracy, surface quality, strength, hardness, etc., to ensure that the steel parts produced meet customer requirements.

10. Parts packaging and delivery

Packaging: Pack and ship the parts that have passed the quality inspection, and select the appropriate packaging method and the appropriate logistics method (such as air, sea, and land transportation) to deliver them to customers on time.

If you want to custom parts, please send me the design drawings and 3D drawings of theparts you want to customize by email, and we will calculate an accurate price for you bylooking at the detailed part parameters and 3D model.