Manufacturing Process of Cast Copper Parts

Copper Sand Casting

Copper sand casting uses sand as the mold material, then pours the molten copper solution into the mold, removes the casting after cooling, and cleans and post-processes it.

· The mold manufacturing cost is low and can be used many times

· Casts large and medium-sized copper castings with complex shapes and large sizes.

· Suitable for small, medium and large batch production.

Copper Die Casting

Copper die casting is the process of injecting molten copper into a metal mold cavity under high pressure to quickly fill the cavity and solidify it. It is suitable for mass production of thin-walled, complex, and high-precision parts.

· The copper casting surface is smooth and the dimensional accuracy is high.

· The production cycle is short and suitable for mass production.

· The metal loss is small and the cooling in the mold is fast.

Copper Gravity Casting

Copper gravity casting usually uses metal molds, and the copper solidifies and forms under natural conditions. It is suitable for parts of medium complexity.

· The mold cost is low and suitable for small and medium batch production.

· Larger parts can be produced with better density.

· The price of parts is low.

Copper Investment Casting

Copper investment casting uses soluble or combustible casting molds (such as wax molds) to make castings, and is often used to make copper parts with complex shapes and high precision requirements.

· High surface quality

· No need for a lot of post-processing

· Suitable for small batches and high precision copper parts

Machining

Machining is a post-processing process for copper castings, which improves the accuracy, surface quality and functionality of castings through fine processing.

· Optimize appearance quality

· Improve part structure and function

· Process thin walls and complex shapes

Surface Treatment

Surface treatment can transform the surface of copper castings by physical, chemical or mechanical means to improve the surface quality of castings, increase their durability, and improve appearance and functionality.

· Improve surface hardness

· Improve appearance and improve dimensional accuracy

· Improve adhesion and corrosion resistance

Different Materials of Cast Copper Alloy

1. Brass

Brass is an alloy of copper and zinc, offers excellent corrosion resistance, good mechanical properties, an attractive golden appearance, good castability, machinability, and cost-effectiveness, making it suitable for a variety of decorative and functional applications.

· Excellent Corrosion Resistance: Particularly resistant to seawater, atmospheric exposure, and many chemical environments, making it ideal for marine applications.

· Good Machinability: Among the best machinability ratings of all metals, producing clean chips and excellent surface finishes with minimal tool wear.

· Antimicrobial Properties: Natural bacteriostatic properties make it suitable for medical, food handling, and sanitary applications.

· Good Castability and Pressure Tightness: Fills molds readily and produces sound castings with good dimensional accuracy and pressure tightness.

· Attractive Appearance: Golden color and ability to take high polish make it popular for architectural and decorative applications.

Brass Castings by Simis Copper Foundry:

Marine hardware and fittings; valves, pumps and plumbing components; architectural door handles and fixtures; musical instruments; electrical connectors and components; decorative art pieces and sculptures.

Brass Casting Grades Used by Simis Copper Foundry:

· Low Zinc Brasses (Red Brasses, Zinc < 15%)

Common Applications: Plumbing valves and fittings, pump components, corrosion-resistant marine hardware.

Common Grades: ASTM C83600 (Ounce metal, Cu85Zn5Pb5Sn5), C84400 (Cu81Zn3Pb7Sn4)

· High Zinc Brasses (Yellow Brasses, Zinc 15-40%)

Common Applications: General hardware, decorative items, architectural fittings, and non-critical mechanical components.

Common Grades: ASTM C85800 (Cu60Zn38Pb2), C86200 (Cu64Zn34Pb2)

· Leaded Brasses

Common Applications: High-volume machined components, valves, fittings, and gears requiring excellent machinability.

Common Grades: ASTM C84400 (Cu81Zn3Pb7Sn4), C85700 (Cu63Zn34Pb3)

· Silicon Brasses

Common Applications: Pressure-containing components, marine hardware, and applications requiring high strength and corrosion resistance.

Common Grades: ASTM C87500 (Cu81Zn14Si4), C87800 (Cu80Zn15Si4)

2. Aluminum Bronze

Aluminum bronze is an alloy of copper and aluminum that offers exceptional strength, excellent wear resistance, and excellent corrosion resistance. Appropriate heat treatment is typically used to optimize the balance between strength and toughness for specific applications. Aluminum bronze possesses the highest mechanical properties among copper-based alloys, making it an ideal choice for the most demanding industrial applications.

· Exceptional Strength and Hardness: Provide the highest tensile strength and hardness of all copper alloys, comparable to some grades of steel.

· Outstanding Wear Resistance: Excellent resistance to wear, galling, and metal-to-metal contact, even under high load conditions.

· Superior Corrosion Resistance: Highly resistant to seawater, sulfuric acid, and other aggressive chemicals, outperforming most other copper alloys.

· Good High-Temperature Performance: Maintain mechanical properties at elevated temperatures up to 400°C (750°F).

· Excellent Casting Properties: Good fluidity and low shrinkage produce sound, dense castings with good dimensional accuracy.

Aluminum Bronze Castings by Simis Copper Foundry:

Heavy-duty bearings and bushings; gear components and worm wheels; valve stems and seats; pump impellers and casings; marine hardware and propeller components; chemical processing equipment; mining machinery components.

Aluminum Bronze Casting Grades Used by Simis Copper Foundry:

· Single-Phase Aluminum Bronzes (Al < 8%)

Common Applications: Chemical process equipment, seawater piping systems, and applications requiring good formability.

Common Grades: ASTM C60800 (Cu92Al8), C61000 (Cu92Al8)

· Duplex Aluminum Bronzes (Al 8-11%)

Common Applications: General purpose high-strength bearings, gears, valve components, and marine hardware.

Common Grades: ASTM C95400 (Cu85Al11Fe4), C95500 (Cu81Al11Ni4Fe4)

· Complex Aluminum Bronzes (with Ni, Fe, Mn additions)

Common Applications: Severe service applications in chemical processing, marine engineering, and high-temperature service.

Common Grades: ASTM C95700 (Cu82Al11Ni4Fe3), C95800 (Cu81Al9Ni5Fe4)

3. Tin Bronze

Tin bronze is a traditional copper-tin alloy with excellent wear resistance and good corrosion resistance. Its natural lubricity, compatibility with steel shafts (bearing properties), and mechanical properties make it an ideal choice for high-load, low-speed applications and various industrial environments.

· Excellent Wear Resistance: Provides outstanding performance against friction and wear, making them ideal for bearing surfaces and sliding applications.

· Good Corrosion Resistance: Highly resistant to seawater, atmospheric corrosion, and many chemicals, with excellent resistance to stress corrosion cracking.

· Good Mechanical Properties: Offers good strength and hardness combined with reasonable ductility and impact resistance.

· Excellent Casting Properties: Good fluidity and low shrinkage tendency produce sound castings with good dimensional accuracy.

· Good Machinability: Machines to excellent surface finishes, though cutting characteristics vary with tin content.

Tin Bronze Castings by Simis Copper Foundry:

Bushings, bearings, and thrust washers; gears and worm wheels; valve components and pump parts; marine hardware and propeller fittings; architectural elements and sculptures; electrical contacts and springs.

Tin Bronze Casting Grades Used by Simis Copper Foundry:

· Low Tin Bronzes (Sn < 8%)

Common Applications: General purpose bearings, valve components, pump parts, and marine fittings.

Common Grades: ASTM C90500 (Cu88Sn10Zn2), C90700 (Cu89Sn11)

· High Tin Bronzes (Sn 8-12%)

Common Applications: High-load bearings, worm gears, heavy machinery components, and industrial bearings.

Common Grades: ASTM C90800 (Cu88Sn12), C90900 (Cu87Sn13)

· Phosphor Bronzes (with P addition)

Common Applications: Electrical springs, contacts, bellows, and precision instrument components.

Common Grades: ASTM C51000 (Cu95Sn5P0.2), C52100 (Cu92Sn8P0.3)

· Leaded Tin Bronzes

Common Applications: High-speed bearings, bushings, and applications where lubrication may be marginal.

Common Grades: ASTM C93200 (Cu83Sn7Pb7Zn3), C93400 (Cu84Sn8Pb8)

4. Other Bronze / Copper Alloy

Bronze is an alloy of copper with tin or other elements (such as aluminum, phosphorus, and manganese). It offers high strength, wear resistance, and corrosion resistance, making it suitable for parts subject to high loads and friction. Compared to brass, bronze has a wider range of compositions, allowing optimized alloys to be selected based on specific requirements for strength, wear resistance, corrosion resistance, and cost-effectiveness. It is an ideal choice for copper castings in high-load, low-speed applications and harsh environments.

· Excellent Wear Resistance: Provides outstanding performance against friction and wear, making it ideal for bearing surfaces and gears.

· Good Corrosion Resistance: Highly resistant to seawater, chemicals, and atmospheric corrosion, particularly stress corrosion cracking.

· Good Mechanical Properties: Offers higher strength and hardness than most brasses while maintaining good ductility.

· Excellent Casting Properties: Fills molds readily and produces sound castings with good dimensional stability.

· Good Machinability: Machines to excellent surface finishes, though generally not as easily as leaded brasses.

Bronze Castings by Simis Copper Foundry:

Bushings, bearings, and thrust washers; valve components and pump parts; architectural fittings.

Bronze Casting Grades Used by Simis Copper Foundry:

· Silicon Bronzes

Common Applications: Valve components, pump parts, architectural fittings, and electrical connectors.

Common Grades: ASTM C87500 (Cu91Si4Zn4), C87800 (Cu90Si4Zn4)

· Leaded Bronzes

Common Applications: High-load, low-speed bearings, bushings, and thrust washers where lubrication may be marginal.

Common Grades: ASTM C93200 (Cu83Sn7Pb7Zn3), C93800 (Cu78Sn7Pb15)

1. Brass

Brass is an alloy of copper and zinc, offers excellent corrosion resistance, good mechanical properties, an attractive golden appearance, good castability, machinability, and cost-effectiveness, making it suitable for a variety of decorative and functional applications.

· Excellent Corrosion Resistance: Particularly resistant to seawater, atmospheric exposure, and many chemical environments, making it ideal for marine applications.

· Good Machinability: Among the best machinability ratings of all metals, producing clean chips and excellent surface finishes with minimal tool wear.

· Antimicrobial Properties: Natural bacteriostatic properties make it suitable for medical, food handling, and sanitary applications.

· Good Castability and Pressure Tightness: Fills molds readily and produces sound castings with good dimensional accuracy and pressure tightness.

· Attractive Appearance: Golden color and ability to take high polish make it popular for architectural and decorative applications.

Brass Castings by Simis Copper Foundry:

Marine hardware and fittings; valves, pumps and plumbing components; architectural door handles and fixtures; musical instruments; electrical connectors and components; decorative art pieces and sculptures.

Brass Casting Grades Used by Simis Copper Foundry:

· Low Zinc Brasses (Red Brasses, Zinc < 15%)

Common Applications: Plumbing valves and fittings, pump components, corrosion-resistant marine hardware.

Common Grades: ASTM C83600 (Ounce metal, Cu85Zn5Pb5Sn5), C84400 (Cu81Zn3Pb7Sn4)

· High Zinc Brasses (Yellow Brasses, Zinc 15-40%)

Common Applications: General hardware, decorative items, architectural fittings, and non-critical mechanical components.

Common Grades: ASTM C85800 (Cu60Zn38Pb2), C86200 (Cu64Zn34Pb2)

· Leaded Brasses

Common Applications: High-volume machined components, valves, fittings, and gears requiring excellent machinability.

Common Grades: ASTM C84400 (Cu81Zn3Pb7Sn4), C85700 (Cu63Zn34Pb3)

· Silicon Brasses

Common Applications: Pressure-containing components, marine hardware, and applications requiring high strength and corrosion resistance.

Common Grades: ASTM C87500 (Cu81Zn14Si4), C87800 (Cu80Zn15Si4)

2. Aluminum Bronze

Aluminum bronze is an alloy of copper and aluminum that offers exceptional strength, excellent wear resistance, and excellent corrosion resistance. Appropriate heat treatment is typically used to optimize the balance between strength and toughness for specific applications. Aluminum bronze possesses the highest mechanical properties among copper-based alloys, making it an ideal choice for the most demanding industrial applications.

· Exceptional Strength and Hardness: Provide the highest tensile strength and hardness of all copper alloys, comparable to some grades of steel.

· Outstanding Wear Resistance: Excellent resistance to wear, galling, and metal-to-metal contact, even under high load conditions.

· Superior Corrosion Resistance: Highly resistant to seawater, sulfuric acid, and other aggressive chemicals, outperforming most other copper alloys.

· Good High-Temperature Performance: Maintain mechanical properties at elevated temperatures up to 400°C (750°F).

· Excellent Casting Properties: Good fluidity and low shrinkage produce sound, dense castings with good dimensional accuracy.

Aluminum Bronze Castings by Simis Copper Foundry:

Heavy-duty bearings and bushings; gear components and worm wheels; valve stems and seats; pump impellers and casings; marine hardware and propeller components; chemical processing equipment; mining machinery components.

Aluminum Bronze Casting Grades Used by Simis Copper Foundry:

· Single-Phase Aluminum Bronzes (Al < 8%)

Common Applications: Chemical process equipment, seawater piping systems, and applications requiring good formability.

Common Grades: ASTM C60800 (Cu92Al8), C61000 (Cu92Al8)

· Duplex Aluminum Bronzes (Al 8-11%)

Common Applications: General purpose high-strength bearings, gears, valve components, and marine hardware.

Common Grades: ASTM C95400 (Cu85Al11Fe4), C95500 (Cu81Al11Ni4Fe4)

· Complex Aluminum Bronzes (with Ni, Fe, Mn additions)

Common Applications: Severe service applications in chemical processing, marine engineering, and high-temperature service.

Common Grades: ASTM C95700 (Cu82Al11Ni4Fe3), C95800 (Cu81Al9Ni5Fe4)

3. Tin Bronze

Tin bronze is a traditional copper-tin alloy with excellent wear resistance and good corrosion resistance. Its natural lubricity, compatibility with steel shafts (bearing properties), and mechanical properties make it an ideal choice for high-load, low-speed applications and various industrial environments.

· Excellent Wear Resistance: Provides outstanding performance against friction and wear, making them ideal for bearing surfaces and sliding applications.

· Good Corrosion Resistance: Highly resistant to seawater, atmospheric corrosion, and many chemicals, with excellent resistance to stress corrosion cracking.

· Good Mechanical Properties: Offers good strength and hardness combined with reasonable ductility and impact resistance.

· Excellent Casting Properties: Good fluidity and low shrinkage tendency produce sound castings with good dimensional accuracy.

· Good Machinability: Machines to excellent surface finishes, though cutting characteristics vary with tin content.

Tin Bronze Castings by Simis Copper Foundry:

Bushings, bearings, and thrust washers; gears and worm wheels; valve components and pump parts; marine hardware and propeller fittings; architectural elements and sculptures; electrical contacts and springs.

Tin Bronze Casting Grades Used by Simis Copper Foundry:

· Low Tin Bronzes (Sn < 8%)

Common Applications: General purpose bearings, valve components, pump parts, and marine fittings.

Common Grades: ASTM C90500 (Cu88Sn10Zn2), C90700 (Cu89Sn11)

· High Tin Bronzes (Sn 8-12%)

Common Applications: High-load bearings, worm gears, heavy machinery components, and industrial bearings.

Common Grades: ASTM C90800 (Cu88Sn12), C90900 (Cu87Sn13)

· Phosphor Bronzes (with P addition)

Common Applications: Electrical springs, contacts, bellows, and precision instrument components.

Common Grades: ASTM C51000 (Cu95Sn5P0.2), C52100 (Cu92Sn8P0.3)

· Leaded Tin Bronzes

Common Applications: High-speed bearings, bushings, and applications where lubrication may be marginal.

Common Grades: ASTM C93200 (Cu83Sn7Pb7Zn3), C93400 (Cu84Sn8Pb8)

4. Other Bronze / Copper Alloy

Bronze is an alloy of copper with tin or other elements (such as aluminum, phosphorus, and manganese). It offers high strength, wear resistance, and corrosion resistance, making it suitable for parts subject to high loads and friction. Compared to brass, bronze has a wider range of compositions, allowing optimized alloys to be selected based on specific requirements for strength, wear resistance, corrosion resistance, and cost-effectiveness. It is an ideal choice for copper castings in high-load, low-speed applications and harsh environments.

· Excellent Wear Resistance: Provides outstanding performance against friction and wear, making it ideal for bearing surfaces and gears.

· Good Corrosion Resistance: Highly resistant to seawater, chemicals, and atmospheric corrosion, particularly stress corrosion cracking.

· Good Mechanical Properties: Offers higher strength and hardness than most brasses while maintaining good ductility.

· Excellent Casting Properties: Fills molds readily and produces sound castings with good dimensional stability.

· Good Machinability: Machines to excellent surface finishes, though generally not as easily as leaded brasses.

Bronze Castings by Simis Copper Foundry:

Bushings, bearings, and thrust washers; valve components and pump parts; architectural fittings.

Bronze Casting Grades Used by Simis Copper Foundry:

· Silicon Bronzes

Common Applications: Valve components, pump parts, architectural fittings, and electrical connectors.

Common Grades: ASTM C87500 (Cu91Si4Zn4), C87800 (Cu90Si4Zn4)

· Leaded Bronzes

Common Applications: High-load, low-speed bearings, bushings, and thrust washers where lubrication may be marginal.

Common Grades: ASTM C93200 (Cu83Sn7Pb7Zn3), C93800 (Cu78Sn7Pb15)

Application of Copper Alloy Castings

Custom Copper Alloy Castings by Simis Foundry

Copper Alloy Castings Company's Custom Steps

Confirm customization requirements

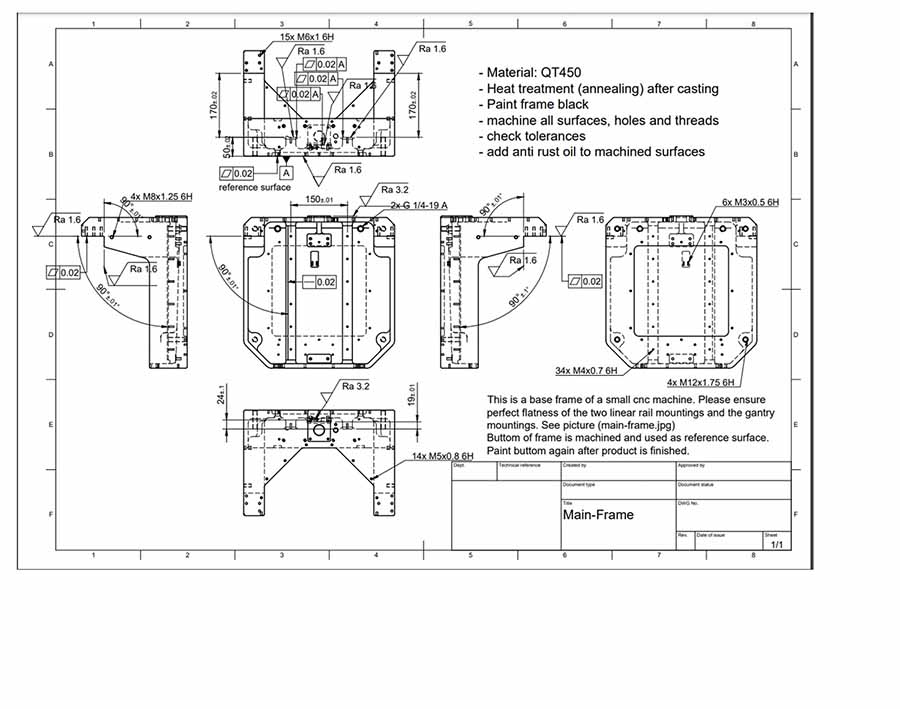

1. Provide detailed design documents or samples of parts

The engineering team will review the 3D drawings (CAD models) and corresponding processing plans provided by customers to ensure that they meet manufacturing requirements.

Samples: If customers provide samples, we can also produce according to samples.

2. Confirm the material of the copper alloy casting

Choose the appropriate cast copper material according to the use environment, technical requirements or customer requirements of the parts. We will give reasonable suggestions based on the price, mechanical properties, wear resistance, corrosion resistance, etc. of the materials.

3. Confirm the copper alloy casting process

Determine the appropriate casting process based on customer needs and part price, shape, size, precision, material, etc.

4. Confirm the requirements for various product attributes

Confirm the various performance requirements of the parts under the casting process and materials, such as strength, hardness, wear resistance, corrosion resistance, etc.

According to the drawings and product requirements, confirm the dimensional tolerance and precision requirements, surface roughness, appearance quality and other requirements of the product.

5. Make molds and samples

Make casting molds that meet the requirements according to the drawings or samples provided by the customer; and cast the selected casting materials through the corresponding process to produce the first batch of samples

6. Comprehensive inspection of samples

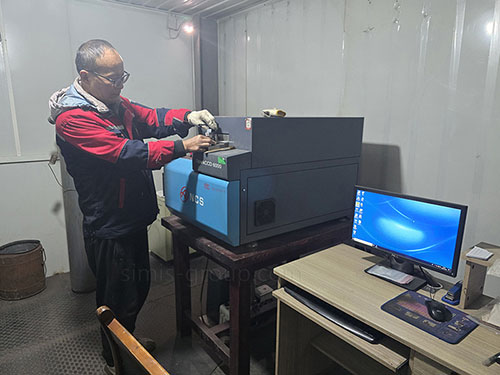

The produced samples will be fully inspected, including size and tolerance inspection, performance test, chemical composition analysis, non-destructive testing and other test reports.

7. Mass production

After the samples are confirmed and approved by the customer, arrange the mass production plan according to the order requirements and prepare the production materials.

Production and quality control

8. Quality control in mass production

We implement strict quality control measures during the production process to ensure that the quality of each copper casting in mass production meets customer requirements.

Production process quality monitoring: Regular sampling during the production process to check the size, appearance, physical properties, etc. of steel castings to ensure the consistency of each batch of parts.

Equipment inspection: Regularly inspect production equipment to avoid production deviations due to equipment failure.

9. Product quality inspection after production

Multiple inspections by multiple people: We will arrange different inspectors to conduct multiple random inspections on the final product, including dimensional accuracy, surface quality, strength, hardness, etc., to ensure that the parts produced meet customer requirements.

Quality inspection report: Provide a detailed quality inspection report for each copper casting inspected.

10. Parts packaging and delivery

Packaging: For parts that pass the quality inspection, pack and ship them, choose the appropriate packaging method and the appropriate logistics method (such as air, sea, and land transportation) to avoid damage during transportation and deliver them to customers on time.

If you want to custom parts, please send me the design drawings and 3D drawings of theparts you want to customize by email, and we will calculate an accurate price for you bylooking at the detailed part parameters and 3D model.