Custom Metal Parts For Industrial Machinery

In the industrial machinery manufacturing industry, castings can manufacture parts with complex shapes, and are mostly used for large, complex, and corrosion-resistant parts; forgings have excellent mechanical properties and high strength, and are suitable for parts that require high strength, good wear resistance, and high precision. Customized castings and forgings can not only improve the reliability and service life of mechanical equipment, but also meet the performance requirements in various extreme working environments.

Industrial Machinery Parts Classification

1. Transmission system

The transmission system is the core link of industrial machinery operation, which efficiently transmits the energy of the power source to the working parts. Castings are mostly used for complex housings and bases to provide good structural stability; forgings are responsible for transmitting torque and bearing dynamic loads, ensuring the high precision, high reliability and durability of the system.

· Castings: Gearbox housing, Clutch housing, Sprocket seat...

· Forgings: Gear, Transmission shaft, Universal joint, Sprocket...

2. Power system

The power system is the "heart" of mechanical equipment, providing continuous energy output for the equipment. In this category, castings are mainly used for complex and high-temperature resistant parts such as housings and cylinders; forgings are used for core parts that withstand high-intensity movement.

· Castings: engine cylinder block and cylinder head, turbine housing, oil pan...

· Forgings: crankshaft, connecting rod, flywheel, camshaft...

3. Hydraulic system

The hydraulic system is mainly responsible for achieving precise power transmission and control in industrial machinery. Castings are often used in pump housings and valve bodies with complex inner cavities to ensure efficient flow of hydraulic oil; forgings are used for high-pressure load-bearing parts such as piston rods and hydraulic joints, providing excellent durability and impact resistance.

· Castings: hydraulic valve body, pump housing, cylinder end cover...

· Forgings: piston rod, gear pump gear, hydraulic joint...

4. Chassis and Travel System

Chassis and travel system provide movement and support capabilities for mechanical equipment, and are the basis for the stability of equipment operation. Castings are usually used for large support parts such as wheel hubs and track rollers to provide stability and impact resistance; forgings are used for key components such as drive shafts and pins that require high strength and wear resistance.

· Castings: Track rollers, track rollers, chassis frames...

· Forgings: Track shoes, drive wheels, pins and bushings...

5. Lifting and load-bearing system

The lifting and load-bearing system is an important part of mechanical equipment for lifting and moving heavy objects. Castings mainly provide large bases and structural supports, and forgings are used for key components such as hooks and pulley shafts that bear dynamic loads.

· Castings: crane base, pulley housing...

· Forgings: hooks, pulley shafts, connecting pins...

6. Braking and safety systems

The braking and safety system is a key link in ensuring the safe operation of mechanical equipment. Castings are mostly used for wear-resistant parts such as brake discs and housings, while forgings are used for high-strength brake shafts and connecting rods.

· Castings: brake discs, brake caliper brackets...

· Forgings: brake shafts, brake connecting rods, brake calipers...

7. Working devices and structural parts

Structural parts are the skeleton and frame of industrial machinery, supporting and fixing the normal operation of other parts; working devices are in direct contact with materials or workpieces. Castings are used for large frames, bases and other parts that require high rigidity and stability, as well as buckets and booms with complex structures to provide high-strength support; forgings are used for high-load shafts and connecting parts, as well as bucket teeth, pins and other parts that withstand high impact.

· Castings: excavator buckets, bucket arm articulation seats, frames and bases...

· Forgings: bucket teeth, main arm pins, main beam pins, bucket arm pins, flanges, structural connecting shafts...

Available Materials For Industrial Machinery Parts

Cast Iron

Cast iron is used in industrial machinery for machine frames, housings, and wear-resistant parts. The casting process and subsequent processing achieve complex shapes and stable dimensions.

·Gray Cast Iron

Gray cast iron is sand-casted into machine tool beds, pump bodies, compressor housings, and equipment bases. It offers excellent vibration absorption and maintains machining precision.

·Ductile Iron

Ductile iron, through casting and heat treatment, is used to make gearbox housings, couplings, valve bodies, and heavy-duty support components. It offers high strength and toughness, capable of withstanding impact and fatigue loads.

·Compacted Graphite Iron

Compacted graphite iron has a uniform microstructure, balancing strength and vibration damping properties. It is commonly used in large machine tool beds, compressor cylinders, and pressure equipment components, extending service life and operating stability.

·Alloy Cast Iron

Alloy cast iron, through alloying and heat treatment, is used in wear-resistant bushings, guide rails, and mill liners. It offers excellent wear and heat resistance, making it suitable for high-temperature friction conditions.

Steel

Steel is used in transmission, load-bearing, and safety components of industrial machinery. Strength and precision are ensured through casting, forging, stamping, welding, and machining.

· Carbon Steel

Carbon steel is often forged into shafts, gears, cranks, and connecting rods. Machining ensures precise fit and reliable power transmission.

· Low-Alloy Steel

Low-alloy structural steel is used to manufacture high-strength frames, lifting arms, and crane supports. Welding and heat treatment are used to increase fatigue life.

· Cast Steel

Cast steel is used in pump bodies, large valves, frames, and planetary reducer housings. After casting, machining ensures proper assembly dimensions.

· Stainless Steel

Stainless steel offers excellent corrosion resistance and is used in valve bodies for chemical equipment, food processing machinery parts, piping, and fasteners. It is suitable for use in humid and corrosive environments.

· Wear-Resistant Steel

Wear-resistant steel is used in hopper liners, conveyor scrapers, and crusher hammers, extending equipment maintenance intervals.

Aluminum alloy

Aluminum alloys are used in industrial machinery for lightweight components and heat dissipation. Complex parts are manufactured through die-casting, extrusion, and machining.

· Aluminum-Silicon Alloys

Aluminum-silicon alloys are die-cast into pump casings, compressor end covers, and motor housings, offering excellent heat dissipation and lightweight performance.

· Aluminum-Magnesium Alloys

Aluminum-magnesium alloys are corrosion-resistant and suitable for manufacturing transportation equipment casings, storage tanks, and brackets, enhancing durability.

· High-Strength Aluminum Alloys

High-strength aluminum alloys, after heat treatment and machining, are used in robotic arms, positioning fixtures, and load beams, reducing weight while maintaining rigidity.

· Aluminum Extrusions

Aluminum extrusions are extruded into production line frames, conveyor rails, and equipment brackets, making them easy to cut, assemble, and surface-treat.

Other metal alloys

Under special operating conditions, industrial machinery uses other alloys to meet wear resistance, corrosion resistance, or electrical conductivity requirements.

·Copper and copper alloys

Copper and copper alloys are used in motor windings, conductive bars, slip rings, and wear-resistant bushings to ensure conductivity and lubrication.

Bronze offers excellent wear resistance and is used in worm gears, plain bearings, and bushings, suitable for low-speed, high-load conditions.

Brass is easy to cut and is often used in valve bodies, fittings, and pipe connections, facilitating assembly.

·Nickel-based alloys

Nickel-based alloys offer high-temperature and corrosion resistance and are used in chemical reactor linings and gas turbine components.

·Titanium alloys

Titanium alloys are lightweight and corrosion-resistant and are used in specialty pumps, seawater equipment, and aviation-related industrial machinery.

Cast Iron

Cast iron is used in industrial machinery for machine frames, housings, and wear-resistant parts. The casting process and subsequent processing achieve complex shapes and stable dimensions.

·Gray Cast Iron

Gray cast iron is sand-casted into machine tool beds, pump bodies, compressor housings, and equipment bases. It offers excellent vibration absorption and maintains machining precision.

·Ductile Iron

Ductile iron, through casting and heat treatment, is used to make gearbox housings, couplings, valve bodies, and heavy-duty support components. It offers high strength and toughness, capable of withstanding impact and fatigue loads.

·Compacted Graphite Iron

Compacted graphite iron has a uniform microstructure, balancing strength and vibration damping properties. It is commonly used in large machine tool beds, compressor cylinders, and pressure equipment components, extending service life and operating stability.

·Alloy Cast Iron

Alloy cast iron, through alloying and heat treatment, is used in wear-resistant bushings, guide rails, and mill liners. It offers excellent wear and heat resistance, making it suitable for high-temperature friction conditions.

Steel

Steel is used in transmission, load-bearing, and safety components of industrial machinery. Strength and precision are ensured through casting, forging, stamping, welding, and machining.

· Carbon Steel

Carbon steel is often forged into shafts, gears, cranks, and connecting rods. Machining ensures precise fit and reliable power transmission.

· Low-Alloy Steel

Low-alloy structural steel is used to manufacture high-strength frames, lifting arms, and crane supports. Welding and heat treatment are used to increase fatigue life.

· Cast Steel

Cast steel is used in pump bodies, large valves, frames, and planetary reducer housings. After casting, machining ensures proper assembly dimensions.

· Stainless Steel

Stainless steel offers excellent corrosion resistance and is used in valve bodies for chemical equipment, food processing machinery parts, piping, and fasteners. It is suitable for use in humid and corrosive environments.

· Wear-Resistant Steel

Wear-resistant steel is used in hopper liners, conveyor scrapers, and crusher hammers, extending equipment maintenance intervals.

Aluminum alloy

Aluminum alloys are used in industrial machinery for lightweight components and heat dissipation. Complex parts are manufactured through die-casting, extrusion, and machining.

· Aluminum-Silicon Alloys

Aluminum-silicon alloys are die-cast into pump casings, compressor end covers, and motor housings, offering excellent heat dissipation and lightweight performance.

· Aluminum-Magnesium Alloys

Aluminum-magnesium alloys are corrosion-resistant and suitable for manufacturing transportation equipment casings, storage tanks, and brackets, enhancing durability.

· High-Strength Aluminum Alloys

High-strength aluminum alloys, after heat treatment and machining, are used in robotic arms, positioning fixtures, and load beams, reducing weight while maintaining rigidity.

· Aluminum Extrusions

Aluminum extrusions are extruded into production line frames, conveyor rails, and equipment brackets, making them easy to cut, assemble, and surface-treat.

Other metal alloys

Under special operating conditions, industrial machinery uses other alloys to meet wear resistance, corrosion resistance, or electrical conductivity requirements.

·Copper and copper alloys

Copper and copper alloys are used in motor windings, conductive bars, slip rings, and wear-resistant bushings to ensure conductivity and lubrication.

Bronze offers excellent wear resistance and is used in worm gears, plain bearings, and bushings, suitable for low-speed, high-load conditions.

Brass is easy to cut and is often used in valve bodies, fittings, and pipe connections, facilitating assembly.

·Nickel-based alloys

Nickel-based alloys offer high-temperature and corrosion resistance and are used in chemical reactor linings and gas turbine components.

·Titanium alloys

Titanium alloys are lightweight and corrosion-resistant and are used in specialty pumps, seawater equipment, and aviation-related industrial machinery.

How To Customize Industrial Machinery Parts

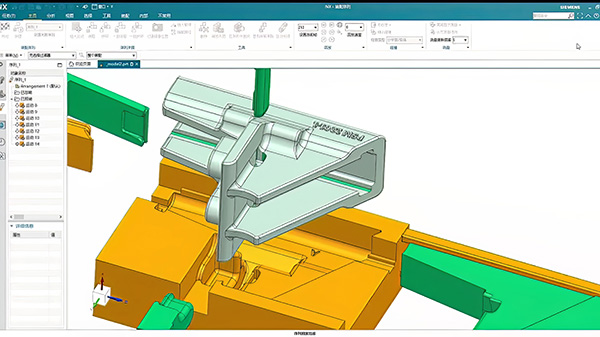

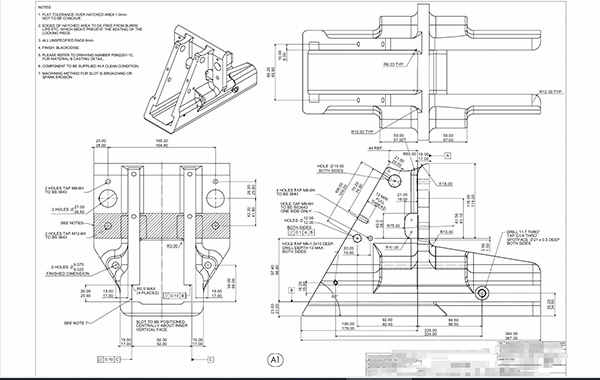

3D Drawing

Processing Drawing

Sample

1. Provide Detailed Design Documents Or Samples

2. Confirm Material/Process/Performance

3. Make Production Molds And Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-production Parts Multiple Quality Inspections

1. Provide Detailed Design Documents Or Samples

2. Confirm Material/Process/Performance

3. Make Production Molds And Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-production Parts Multiple Quality Inspections

Custom Processing of Industrial Machinery Parts

Casting

In the field of industrial machinery, casting processes are used to produce complex shapes or large-sized parts with precise material properties, such as machine tool beds, engine blocks and pump casings. The casting process can efficiently mass-produce complex structural components and provides the flexibility of material selection to meet specific mechanical performance requirements.

Forging

In industrial machinery, forging processes are used to produce highly stressed parts such as gears, shafts and connecting rods, ensuring the durability and reliability of equipment operating under heavy loads or extreme conditions, keeping the machinery running efficiently and safely.

Heat Treatment

In industrial machinery manufacturing, heat treatment processes are used on components such as gears, shafts and cutting tools to improve the performance and service life of parts subject to high stress or friction, ensuring that parts maintain operating efficiency and minimizing the need for maintenance in demanding applications.

Machining

Machining processes produce tight tolerance parts for industrial machinery, such as turbine blades, molds and precision gears, to achieve precise dimensions and surface finishes, ensuring correct assembly of components and efficient operation of machinery, reducing errors and increasing operational reliability.

Sheet Metal Fabrication

In industrial machinery, sheet metal fabrication is used to produce lightweight but strong structural components such as machine housings, frames and brackets that must withstand pressure and harsh environments. It can produce complex-shaped parts in a cost-effective and flexible way, helping to improve the performance and structural integrity of the machinery.

Surface Treatment

In industrial machinery, surface treatment processes can enhance the surface properties of metal components, improving the corrosion resistance, wear resistance and overall durability of the parts. Parts such as gears, bearings and hydraulic components are often surface treated to protect them from environmental damage and extend their service life, ensuring reliable performance and reducing maintenance downtime.